Ask Ron Besuijen

We ask Ron:

Why is it important to understand the relationship and interaction between the human and machine for training?

Ron's Response:

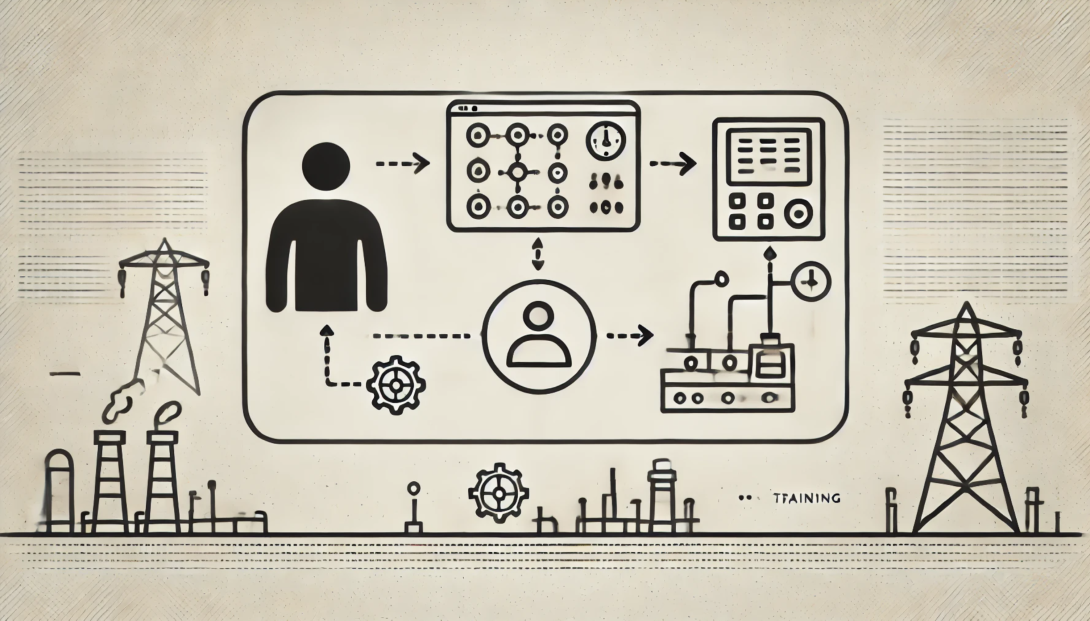

Several years ago, Gary Klein and Joseph Borders completed a study of operators’ mental models that involved watching how they navigated through process upsets on a simulator (This was through the Center for Operator Performance). From this, they developed the Mental Model Matrix. The matrix explores the relationship between the user and the system, as well as the capabilities and limitations of each system.

Operators must understand how the system was designed i.e. process theory and they must also understand how to make the system work in a dynamic environment. You may believe these are the same things, but they are not. Without going into too many details, I can think of several instances where operations have compensated for poor design or unintended consequences when the process is off-normal operating conditions or in a startup. It is important to design these quirks into a training simulator so the operators can be accustomed to them.

It is beneficial if operations understand how the equipment can fail. This will allow them to size up situations faster. There can be any number of problems with transmitters, valves, analyzers, pumps, or equipment fouling. There is a belief that automation, digitalization, and artificial intelligence will solve many problems and generate more profits. They can do both, however, they also come with new challenges. They are only as reliable as the data (The Boeing 737 Max is one example worth noting). I believe that more training will be required for operations to be able to problem solve and troubleshoot these new tools. Simulators are the best way to accomplish this. Testing these tools on a simulator or digital twin before they are implemented will increase their success and minimize process upsets.

The matrix also discusses how operators can become confused from the information they are receiving. Graphics design can make a large difference in minimizing this. This is a huge topic and deserves more research with the user’s input. At the very least a senior panel operator should be involved when the graphics are developed. The graphics should help develop the panel operator’s mental model and enhance their decision-making abilities.

Knowing the capabilities and limitations of the process and the people is critical to maintaining production and safely managing our processes.

| Capabilities | Limitations |

System | How the system works: Parts, connections, causal relationships, process control logic | How the system fails:

|

User | How to make the system work: | How users get confused: |

For more information visit the following: